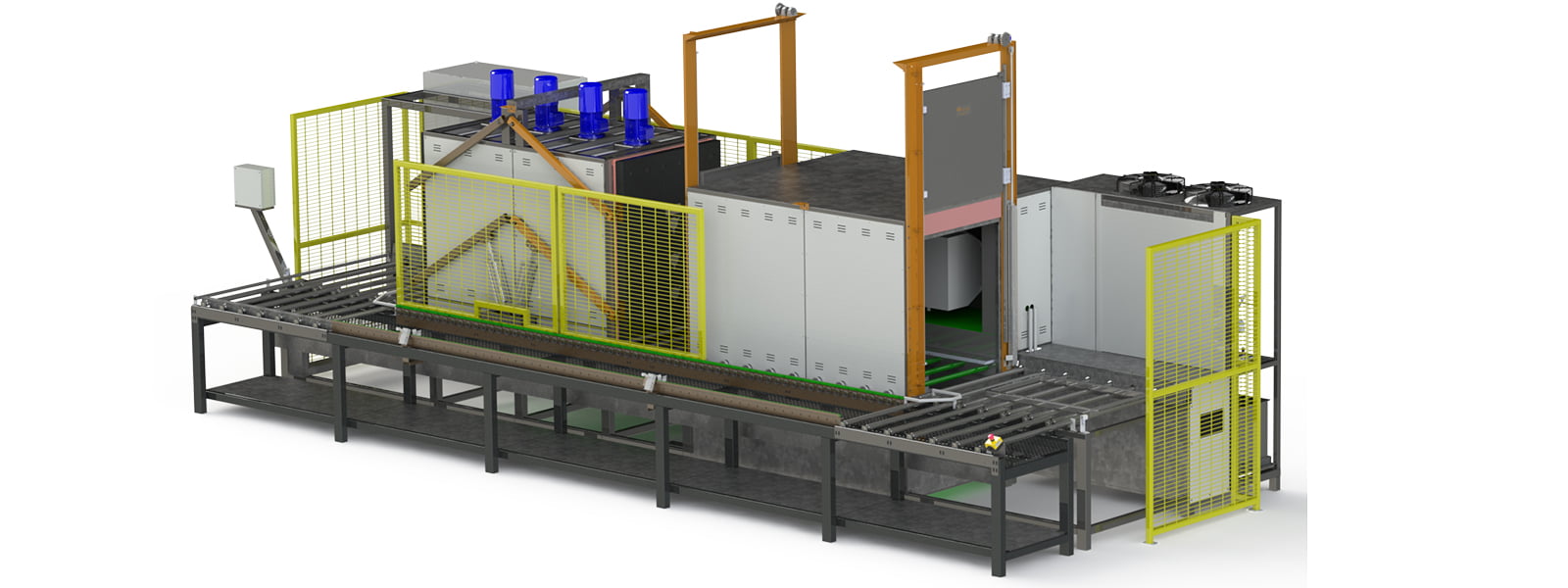

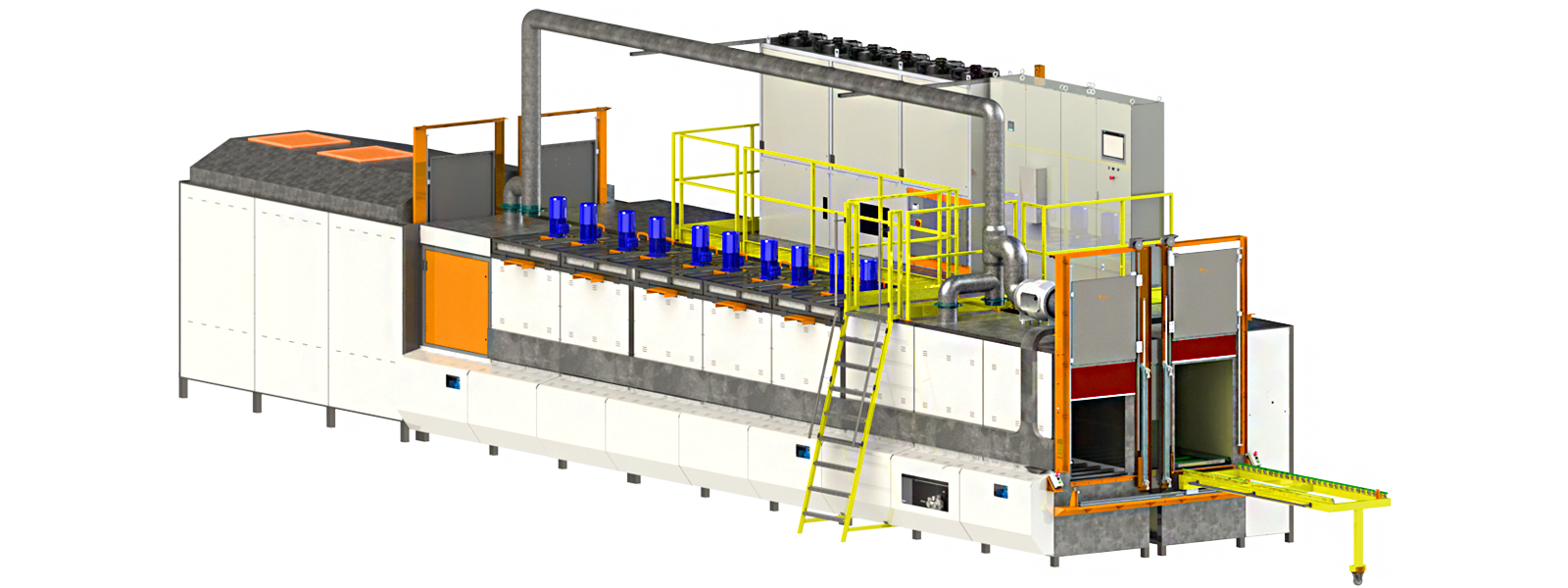

THERMOFORMING

CONVECTION SYSTEMS

Kepka produce Thermoforming Convection Tunnel Kiln based on Innovative Solutions from a new generation of insulation materials, high-temperature and heat-resistant steels with the highest strength, abrasion and operation (continuous and periodic) parameters at high temperatures.

The transport system with smooth adjustment of the time of the product’s passage through the furnace, many independent heating sections with an innovative heating system based on the appropriate correlation of heat transport by convection to radiation, makes our furnaces meet the most demanding technological parameters.