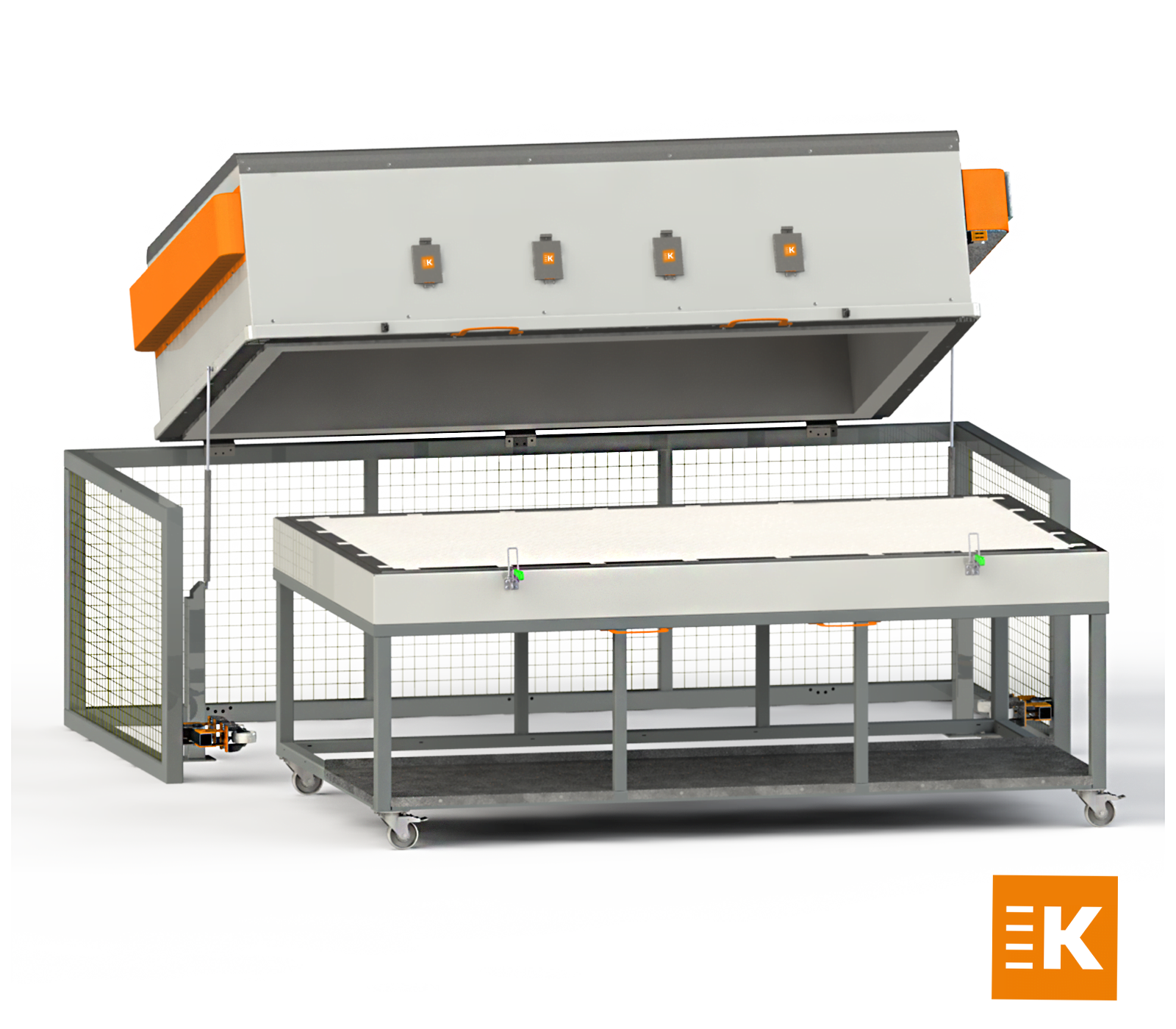

FOURNAISES DE CHAMBRE

POUR FUSION ET VERRE

Four à chambre puissant pour fusion, bombage de verre, production de vitraux et décoration sur verre plat. Precise Thermal Processes – Kepka furnaces guarantee clean and safe work due to specially designed flat surface Kepka furnaces ensuring perfect thermal processes due to heating elements, which ensure an even temperature distribution during fusing or bending overt the entire surface of the table. Fibrous insulation in the furnace lid and fiber materials resistant to thermal shocks and thermal expansion

Le four à chambre Kepka pour le verre et la fusion est le choix parfait pour artiste qui aiment travailler avec glass. It is also an ideal tool for producers, manufacturing, among others, glass shop counters or other products that require glass bending. Thermal insulation with a very conductive thermal conductivity (0.15 W/mK), production from pressed fibrous materials ensures low electricity consumption, quick temperature reaching and uniform cooling. Equal lining of the bottom of the chamber are insulated with fibrous material to eliminate the difference in thermal expansion of ceramic materials, thermal accumulation of insulation and glass. Heating elements are placed on the roof of the working chamber in the form of a spiral in quartz glass tubes – transfert de chaleur par rayonnement, very leveled from the lowest temperatures.

En tant que norme:

- contrôle intelligent – intuitive temperature controllers – Bentrup 707 et Bentrup 705 and Kepka HMI PLC systems

- Tmax 960°C

- precise control without oscillation – a very important parameter during very long processes

- direction de la chambre de travail personnalisable

- easy to assemble – Plug and Play

- isolation multicouche consommation d'énergie réduite

- construction résistante en acier acide

- optional: movable or still table

- direction of door opening – up (pneumatic actuators, additional option: hydraulically opened, electrically opened).

- eco-friendly powder coating of the cover